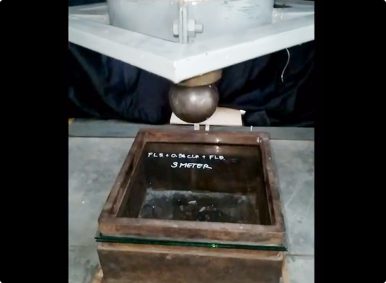

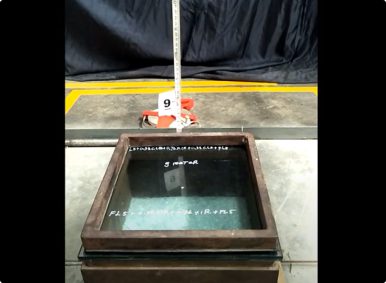

Dean’s Autoglass R&D department has designed and developed the ultimate safety glass for use in the heavy machinery industry where the chance of glass breakage and cabin intrusion is a high risk.

Tests have shown XIR Glass is superior in strength and durability over existing laminated glass in the market. The safety of operators using machines in risk areas is enhanced by its strength, as well as reducing operator fatigue due to the reduction in solar heat gain and noise attenuation properties whilst maintaining maximum visibility.

XIR glass provides a safer and more comfortable work environment, leading to greater productivity.